Operational management of the content creation process of e-mobility content on the website of an automotive manufacturer and optimization of the content as part of the transition to the new brand design.

Scope: 120 person days (PD*)

* PD = Person days à 8 hours

In Germany, e-mobility is no longer a marginal phenomenon. German automakers now produce electric vehicles for the mass market and Tesla has announced plans to build a gigafactory in Berlin-Brandenburg. In many areas of society, the technological shift away from internal combustion engines to electrified propulsion is becoming increasingly apparent. Increasing numbers of electric vehicles are on the road, charging stations dot the cityscape, and after many decades, production factories no longer make engines but batteries. Globally, and in Germany as well, electric car registrations are increasing. In 2019 alone, 62,281 electric cars were newly registered in Germany. As a result of the Paris climate protection agreement entering into force, CO2 emissions in the transport sector are expected to drop significantly. For the EU, the 95 g CO2/km target will apply to newly registered passenger cars from 2021. Since this agreement at the latest, a rethink in vehicle drive technology has been taking place among all stakeholders.

The most important component of electrification is the energy storage system for driving the electric motor. On the way to the high-performance end product, the life cycle of the traction battery begins with the extraction of the required raw materials.

The most important component of electrification is the energy storage system for driving the electric motor.

A battery weighing around 400 kg and with a capacity of 50 kWh primarily contains a great deal of aluminum, steel and plastics, plus around 6 kg of lithium, 10 kg of manganese, 11 kg of cobalt, 32 kg of nickel and 100 kg of graphite. By way of comparison, a smartphone battery requires about 8 g of cobalt and 8 g of lithium; for the traction battery of an electric car, therefore, about a thousand times the amount of these rare raw materials. Cobalt and lithium are the key elements for battery construction, because they are needed for the cathodes – the negative poles during charging. The anodes – the positive poles during charging – are made of graphite, a very common mineral. Every year, hundreds of thousands of tons of cobalt and lithium are mined for the production of batteries and rechargeable batteries. The steady rise in electromobility will additionally increase demand many times over in the coming years. The German Mineral Resources Agency (DERA) expects cobalt demand to increase to 225,000 t/year by 2026 (total production in 2018: 126,000 t), which compares to a global known deposit of around 7.4 million tons.

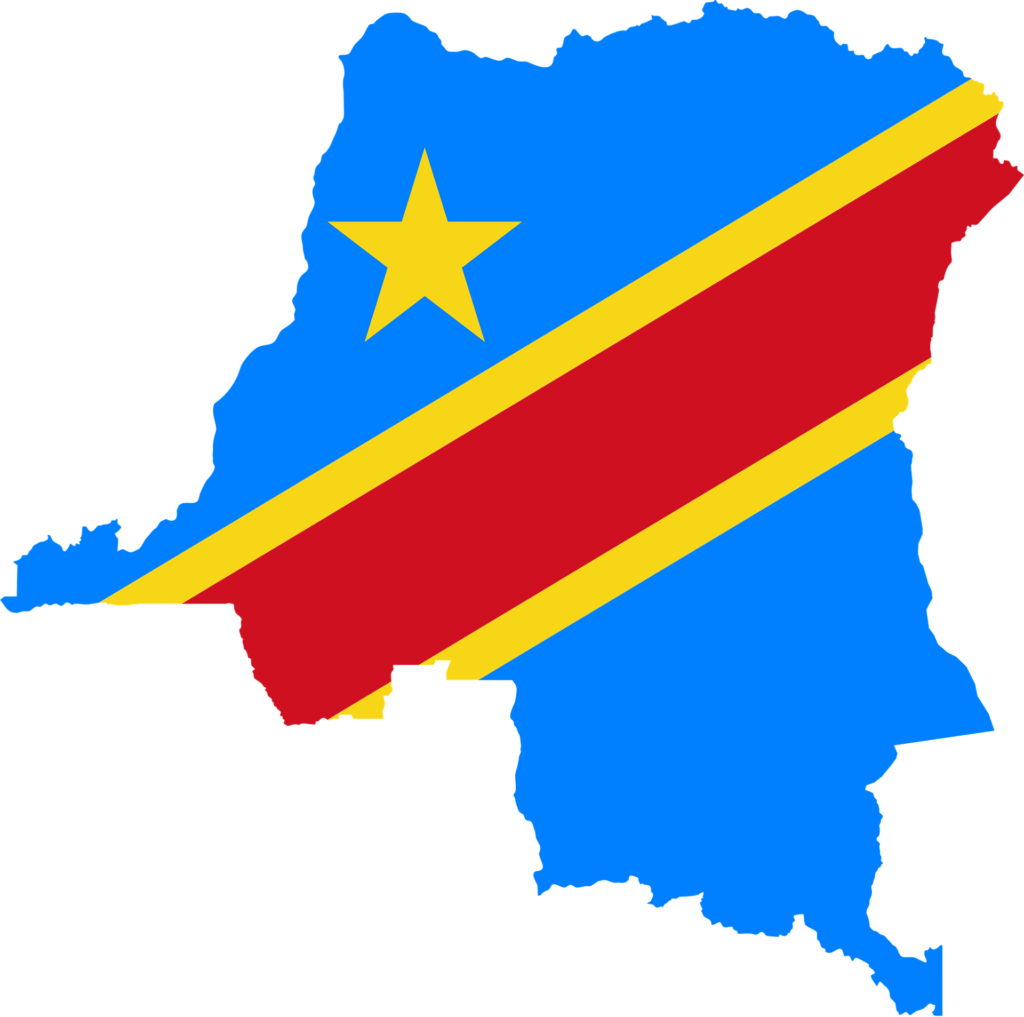

The largest proven deposit of cobalt – at 3.4 million metric tons (Mt), about half of the global reserves – is found in the Democratic Republic of Congo.

80% of the cobalt is mined industrially and 20% individually. Most mines are directly or indirectly under the power of local military leaders, who use the proceeds to finance secondary conflicts of the civil war in Congo. Thousands of children work in the mines, and people often die from fatal work accidents in tunnels and holes. Human rights violations are not taken into consideration. The world’s largest battery manufacturers are based in China, which obtains the cobalt it needs from another Chinese mining group whose subsidiary buys up smaller mines in the Congo, among other things.

German manufacturers try to avoid sourcing cobalt from Congo and buy their raw materials in Australia, for example. The fifth continent has the world’s second-largest cobalt deposit. Cobalt is also found in Canada, Cuba and Russia. In the Philippines, manganese nodules on the seabed contain the rare raw material, which is mined by deep-sea prospecting and thus poses a threat to the marine ecosystem.

Cell manufacturers are already researching methods to reduce the cobalt content in batteries. Tesla, together with its battery manufacturer Panasonic, has already reduced its cobalt content by 2.8%, whereas VW currently requires four times as much for the ID.3. But here, too, the goal is to reduce the cobalt content to below 5% in the medium term. In parallel, research is also being conducted into the development of cobalt-free batteries. Nickel would then be increasingly used instead of cobalt.

Unlike cobalt, lithium, the second key element for battery production, is not particularly rare in geological terms; the challenge lies in the different mining methods of the various deposits. In Chile, for example, the country with the largest lithium deposit in the world, it is extracted from highly pumped groundwater. The companies involved are considered corrupt, to the detriment of the indigenous population. The consequences of lithium mining are parched regions and often untreated wastewater with as yet unexplored ecological damage.

In the context of the new electric vehicles, which are frequently associated with sustainability, the focus is rarely on the ecologically questionable extraction of raw materials. It is therefore all the more gratifying that both the vehicle and battery industries are taking a critical look at the issue. In their efforts to bring ever more powerful batteries to market, they are also evaluating the extraction and origin of raw materials and trying to optimize them in terms of sustainability.

Von Dr. Alexander Erdland, Ralph Hientzsch, Dr. Peter von Koppenfels

After Covid, many things will no longer be the same. Not all of the consequences can be foreseen yet, but some lessons can already be learned. Whether home office or online shopping – during the crisis, the acceptance of digital interaction has noticeably increased. The much-discussed customer interaction seems to have passed the practical test.

Read in the current issue of Versicherungswirtschaft on what insurers should do now.

Download the full article here. (The article is in German.)

Agile process models are gaining ground, especially in software and consumer goods development. In the most frequently used process model, Scrum, the team is made up of three functional roles: Product Owner, Scrum Master and Implementation Team. The product owner is responsible for the object and goal of the product, while the scrum master is responsible for productivity and adherence to the methodology.

In the shared mobility market, sustainable success is essentially based on two factors: a profound understanding of user expectations and a state-of-the-art offering.

From the provider’s point of view, it is also important that the mobility services marketed fit in with the portfolio and stand out from competing offerings.

Digitization is in full swing. Technological developments have a high market penetration and determine how we communicate and consume. Speed is the new currency and determines whether companies can prevail over the competition in the course of digitization. In order to reduce time-to-market many times over and increase IT performance, DevOps is one of the leading ways of working in IT in the future.

DevOps is made up of the two terms Development and Operations and refers to the approach of creating an environment in which software development and IT operations are united and share responsibility for the software lifecycle. In this context, DevOps represents a combination of a mindset, a culture, technical practices and tools. Through a set of different measures, it aims to break down silos between software development and operations, establish a new culture, and thus enable continuous delivery of software. Through communication, continuous integration and continuous delivery, automation and close cooperation, the aim is to bring together all the experts needed to plan, develop, test, release and operate the software in order to promote shared responsibility for the entire software lifecycle. The effects are significantly shorter release cycles, lower time-to-market, significantly fewer failures, higher test coverage and more satisfied employees and customers.

Long gone are the days when a car consisted only of hardware. Today, the car is controlled by over 50 control units through software and, with the help of digital services such as Apple Music or Last Mile Navigation, forms a digital ecosystem for its users. As a rule, IT at car manufacturers is classically organized in silos with their own, sometimes competing targets, which promotes irregular software updates and long deployment times. Tesla in particular, through its pioneering role in over-the-air updates (OTA updates), is creating pressure to release software updates much more frequently than car manufacturers have done so far.

Back in 2013, Scania addressed this issue by introducing cross-functional DevOps teams and automating builds, tests and deployments, enabling teams to deploy multiple times a day if needed. But suppliers to automotive manufacturers can also benefit from the approach, as evidenced by Urban Science, an automotive retail performance expert. Adopting DevOps not only better managed the complexity of the deployment and release process, meeting release deadlines and accelerating deployment. It also increased test coverage through automation and thus system stability.

The transformation to DevOps is a continuous process and requires a vision and clear goals to be achieved by DevOps in the company. It needs an adjustment of the company processes and the support of the management so that the transformation succeeds.

We advise you on whether DevOps is the right approach for your company and whether a transformation is feasible and effective. We also support your project from the initiation of the transformation through the establishment of effective measures to stabilization, so that the desired effects of DevOps are achieved quickly and sustainably.

The advancing digitalisation does not stop at sales. In this area, this means in most cases a strong online presence of the companies. Especially in the business-to-consumer (B2C) sector, the focus is on providing information about the products on offer. Due to the increasing demand for customisation options, their complexity is also growing. This has to be mapped, both on the basis of individual preferences of the customers and their needs.

Among many other areas, the automotive sector in particular is known for almost unlimited possibilities to customise a vehicle. The presentation of information through classic, static websites is often not sufficient in such cases. Therefore, a product configurator helps the user to prepare his purchase decision and to inform himself. The aim here is to offer the customer a suitable product based on their individual wishes and needs.

However, the many different customisation options can also overwhelm the user and dissuade him from his purchase intention. One solution to this challenge is a so-called needs configurator. By means of targeted, abstract questions, a customer’s needs are determined and a suitable configuration proposal for the product is offered. This can then be transferred to the product configurator and further individualised there. Depending on the product and company, the customer can then place an order or be forwarded to the retailer for individual advice.

Consileon is your contact for configurators – both classic and demand-oriented. We not only have expertise in integrating the configurator into a content management system (CMS), but are also specialists in rules and regulations. We have excellent references in the technical specification of applications as well as the connection of further IT systems and the implementation of the international rollout.

In addition, with Ajco & Fiantec we have reliable partners who specialise in the design of these complex sets of rules.

We are also happy to think outside the box with you. For example, you can discuss the following topics with us:

Socioeconomic and technological megatrends such as urbanization, digitization, conscious consumption, or concern for the environment are causing the market for shared mobility services to grow steadily.

Underway for decades, urbanization is leading to the densification of residential areas. The resulting shortage of parking spaces makes owning a car in metropolitan areas unattractive. Car-sharing customers save themselves the hassle by parking the car after the trip at the rental station, in public parking or in a specified neighborhood on the street.

Millennials’ declining incomes compared to previous generations are changing consumer culture. For younger consumers, access to a resource is more important than ownership of it. In addition to economic constraints, a high affinity for the mobile Internet and the increasing threat of environmental risks such as climate change make these consumers receptive to alternative mobility offerings, especially when these are realized with electrically powered vehicles.

Car sharing is in first place. In January 2020, the German BCS association put the number of vehicles in the German car-sharing market at 25,400, which is a good quarter more than in the previous year. The total number of registered customers is 2.3 million.

In addition to private car sharing, which is established in many places, there are premium usage models offered by car manufacturers and corporate car sharing, which is organized partly by external specialists and partly within the company, as an alternative to exclusive company cars. Fleet sharing is a further development of this model. Here, OEMs offer company cars for use by their staff or external interested parties. The use of e-cars in car sharing currently depends above all on the expansion of the charging infrastructure.

In addition, technical innovations such as autonomous driving, automotive IT services, and the trend toward multimodal travel offer starting points for the development of shared mobility models. With a wide range of offers and additional services, it is possible to arrange the fastest, most convenient, cheapest, or most interesting solution for tourists, depending on their mobility needs.

The increasing connectivity among and between providers, users and intelligent accompanying systems opens up further potential for developing or expanding shared mobility services. The possibilities range from individualizable billing systems or GPS-based fleet management to networking the car with the outside world.

Increase the budget, postpone deadlines: These measures are not always enough to get a project out of trouble. Then the advice of methodologists and industry experts is needed who have an overview of the project portfolio and know how the individual projects influence each other. This is exactly what a project management office (PMO) does, a staff function that drives projects forward by providing operational support to their leaders and teams and setting technical accents.

The digital transformation has also reshuffled the cards in the automotive industry. Players from outside the industry are entering the market with partly disruptive business models. With the networking of players and systems, stricter regulatory requirements and the dynamics of demand, the complexity of multi-project and programme management is also increasing. More and more projects are interrelated and interdependent, even across national borders, and must be managed with scarce resources. However, this does not only entail risks, but also opportunities. A methodically and technically competent PMO helps automotive companies to seize the opportunities and control the risks.

Consileon offers two PMO models, generic and sector-specific. Read here which one is right for you: